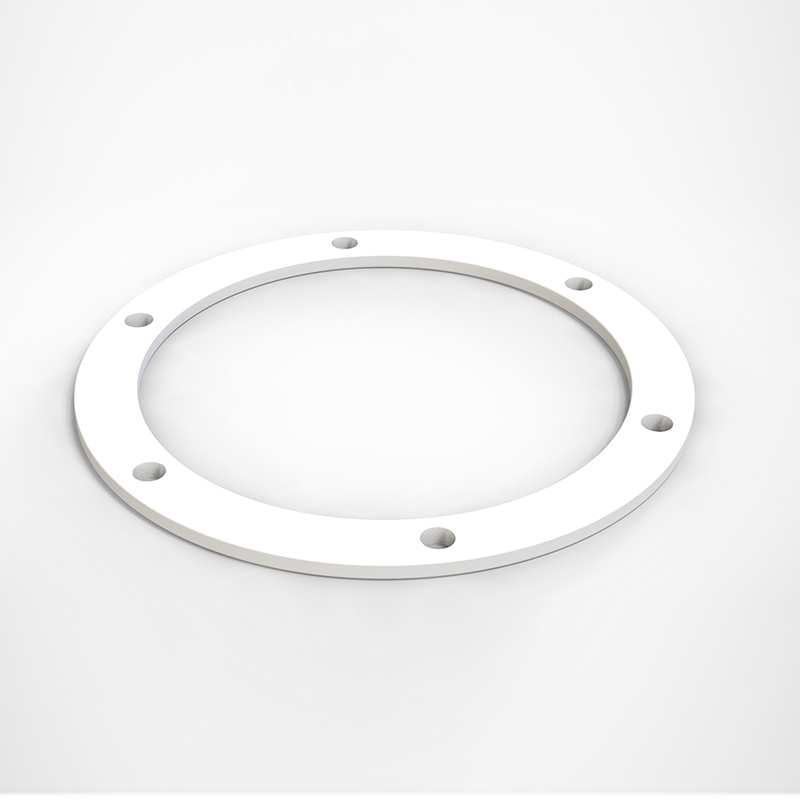

密封垫片

| 垫片 | Gasket |

|---|---|

| 品 名: | 密封垫片 |

| 截 面: | 矩形、梯形、异形定制、按图加工 |

| 材 质: | PTFE、PEEK、PPL、超高分子聚乙烯UHMW-PE、尼龙、聚苯酯、ABS、PC等 |

| 处理: | 开槽、打孔等 |

| 颜色: | 白色、黑色、黄色、蓝色、半透明色 |

| 尺 寸: | 2~3000 mm |

| 温 度: | -200℃~+300℃ |

| 压 力: | 真空~50 MPa |

密封垫片是一种用于填充两个或多个连接面之间的空隙,以防止流体或气体泄漏的机械部件。它们广泛应用于各种工业领域,如汽车、航空航天、制造业、石油化工等,确保设备的安全性和效率。

主要功能:

- 防止泄漏:通过紧密贴合连接面,阻止液体或气体的泄露。

- 补偿表面不平:即使连接面有微小的不平整,垫片也能起到补偿作用,确保密封效果。

- 耐化学腐蚀:根据使用环境的不同,选择不同材料的垫片,以抵抗化学品的侵蚀。

- 热稳定性:在高温或低温环境下保持性能稳定,不易变形。

材料类型:

- 金属垫片:如不锈钢、铜、铝等,适用于高压、高温环境。

- 非金属垫片:如石墨、橡胶、塑料、纤维等,成本较低,适用于中低压环境。

- 复合材料垫片:结合了金属与非金属材料的优点,具有较好的耐温、耐压性能。

应用场合:

- 管道连接:在管道系统中,用于法兰之间的密封。

- 机械设备:发动机、泵、压缩机等设备中的密封部件。

- 压力容器:储罐、反应釜等需要严格密封的容器。

安装注意事项:

- 正确选择垫片规格和材质:根据工作介质、温度、压力等条件选择合适的垫片。

- 检查安装表面:确保接触面干净、无损伤。

- 均匀施力:紧固螺栓时应采用对角线方式,保证垫片受力均匀。

- 避免过度压缩:过度压缩会导致垫片失去弹性,影响密封效果。

密封垫片的选择和正确安装对于确保系统的安全运行至关重要。不同的应用场景可能需要特定类型的垫片,因此在实际应用中应综合考虑各种因素。

Sealing gaskets are mechanical components used to fill the gaps between two or more connection surfaces to prevent fluid or gas leaks. They are widely applied in various industrial fields such as automotive, aerospace, manufacturing, and petrochemicals, ensuring the safety and efficiency of equipment.Main Functions:Preventing leaks: By tightly fitting the connection surfaces, gaskets block the leakage of liquids or gases.Compensating for surface unevenness: Even with slight irregularities in the connection surfaces, gaskets can compensate to ensure a proper seal.Chemical corrosion resistance: Depending on the operating environment, gaskets made from different materials can be selected to withstand chemical erosion.Thermal stability: They maintain stable performance in high or low-temperature environments and are less likely to deform.Types of Materials:Metal gaskets: Such as stainless steel, copper, aluminum, etc., suitable for high-pressure and high-temperature environments.Non-metal gaskets: Such as graphite, rubber, plastic, fibers, etc., which are lower in cost and suitable for medium to low-pressure environments.Composite gaskets: Combining the advantages of both metal and non-metal materials, they have good thermal and pressure resistance.Applications:Pipeline connections: Used for sealing between flanges in pipeline systems.Mechanical equipment: Sealing components in engines, pumps, compressors, and other equipment.Pressure vessels: Containers such as tanks and reaction kettles that require strict sealing.Installation Considerations:Correctly choose gasket specifications and materials: Select appropriate gaskets based on working medium, temperature, and pressure conditions.Check installation surfaces: Ensure contact surfaces are clean and undamaged.Apply force evenly: Use the diagonal method when tightening bolts to ensure uniform pressure on the gasket.Avoid excessive compression: Over-compression can cause the gasket to lose elasticity, affecting the sealing effectiveness.The selection of sealing gaskets and their correct installation are crucial for ensuring the safe operation of systems. Different application scenarios may require specific types of gaskets, so various factors should be considered in practical applications.

待补充